Laser automation of fiber laser cutting machine

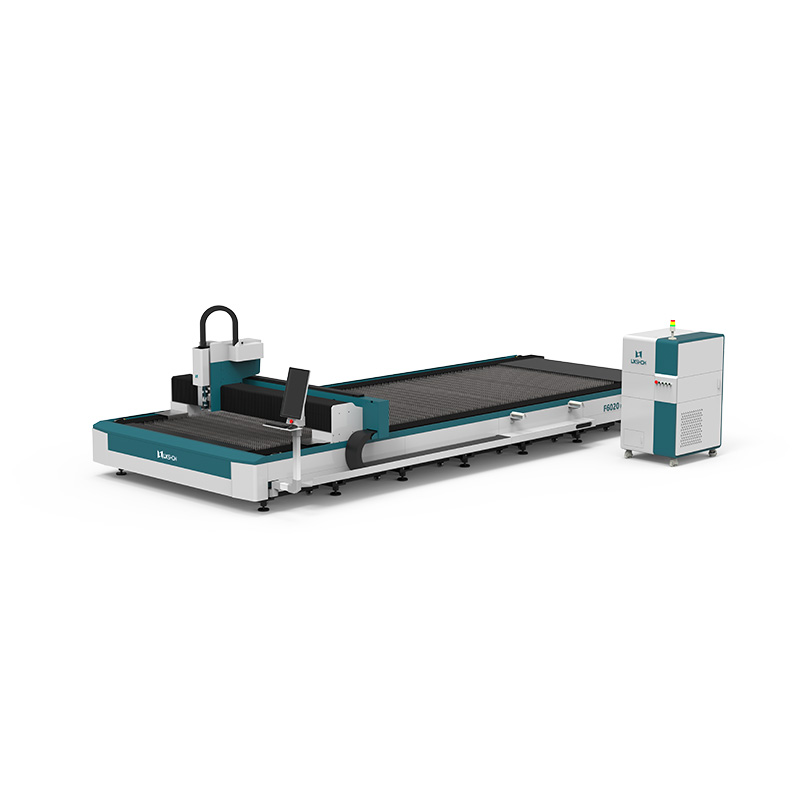

The fiber laser cutting machine has narrow slits, high precision, and good slit roughness. After cutting, there is no need for further processing. The laser processing system itself is a computer system, which can be easily arranged and modified. It is suitable for tempered processing, especially for sheet metal parts with cumbersome appearance and style. The batches are large and the batches are not large, and the product life cycle is not long. Measured from the perspective of technology, economic cost and time, it is not cost-effective to produce molds, and laser cutting is particularly advantageous. The energy density of laser processing is large, the action time is short, the heat affected zone is small, the thermal deformation is small, and the thermal stress is small. In addition, the laser is non-machine contact processing and has no machine stress on the workpiece, which is suitable for precision processing. The high energy density of the laser is sufficient to melt any metal, and it is especially suitable for processing raw materials that are difficult to process by other technological means with high hardness, high brittleness, and high melting point. The processing cost is cheap. One-time investment in equipment is more expensive, but continuous and large-scale processing ultimately lowers the processing cost of each part. The laser is non-contact processing, with low inertia and fast processing speed. It is time-saving and convenient, and the overall compliance is very high.

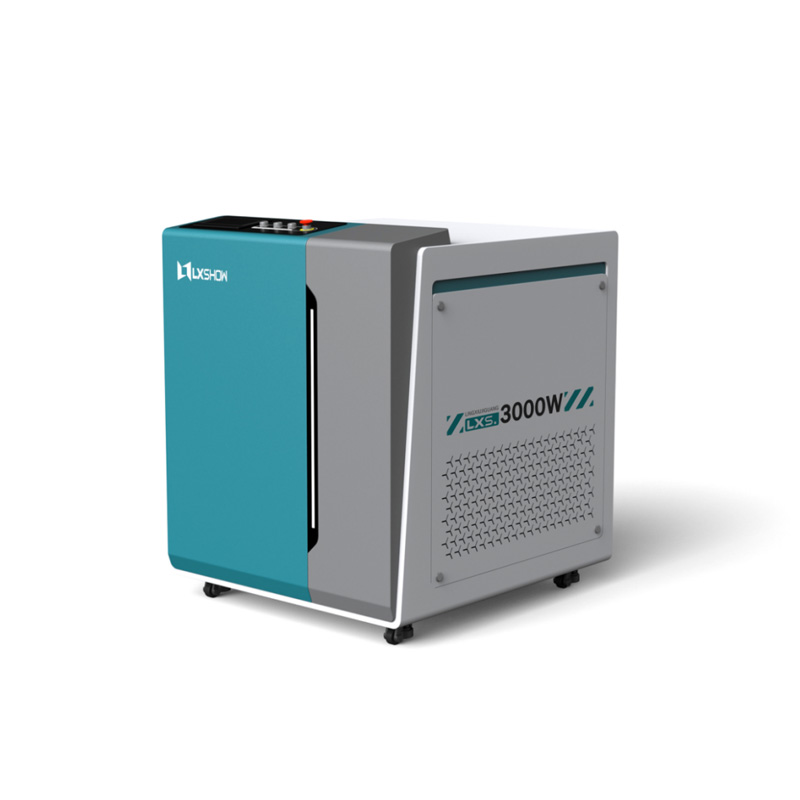

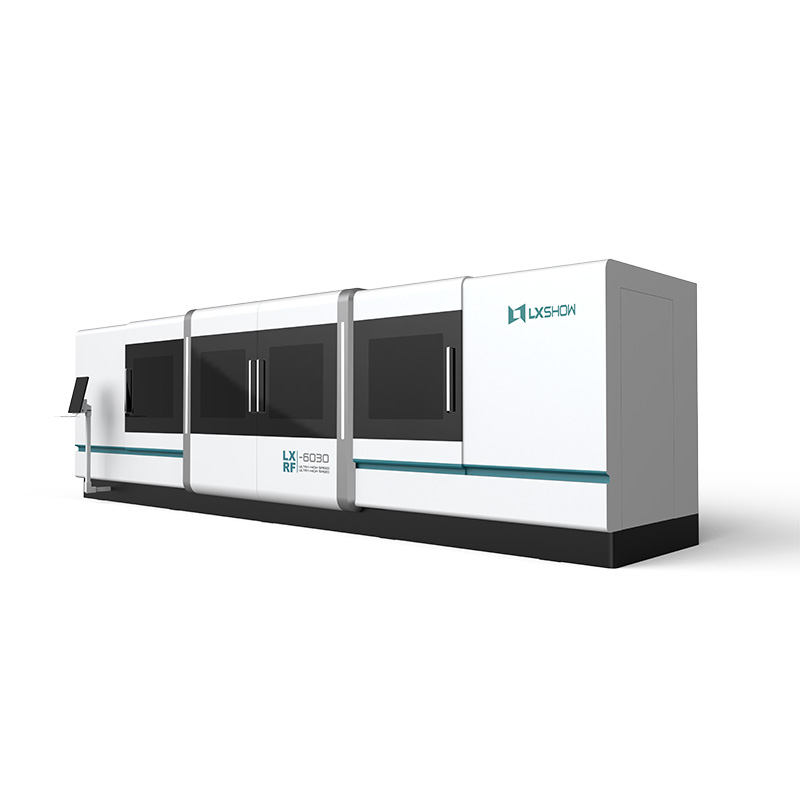

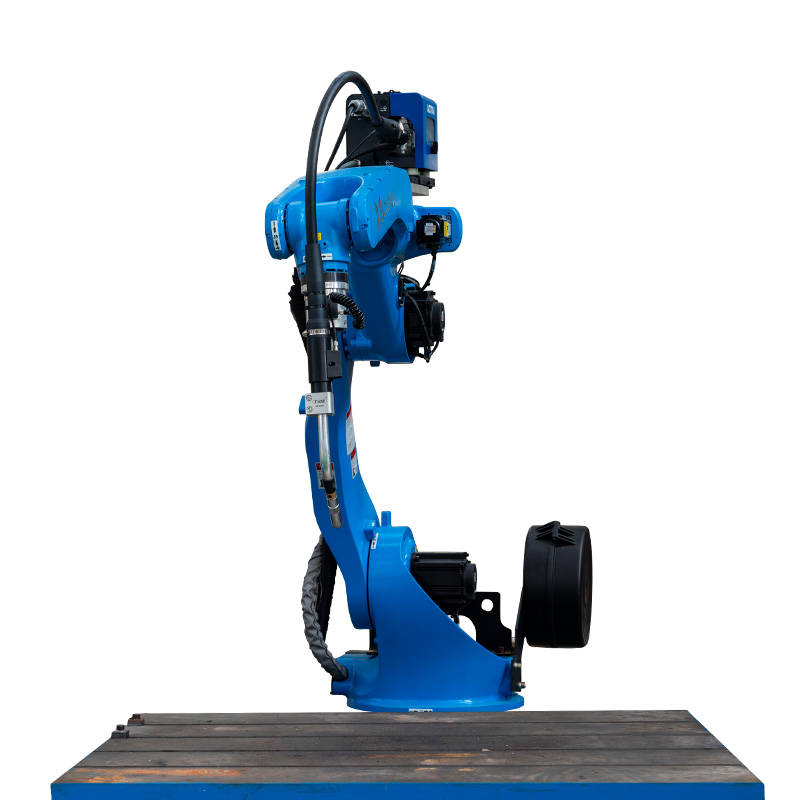

The fiber laser cutting machine laser has a high degree of automation, can be completely enclosed processing, no pollution, low noise, and greatly improves the working environment of the driver. Consequences, the production has moved forward to comply. Because five-axis machine tools are basically imported from abroad at present, the price is extremely high, and the equipment price of more than three to five million yuan is a threshold that is difficult to popularize for the majority of small and medium-sized manufacturers. Moreover, for the current three to four million low-end five-axis laser cutting machines, the selected lasers are basically 2KW fast axial flow C02 lasers, which need to be filled with He, Ne, C02 and other gases, and the charge price is 20 yuan/hour The power consumption of the system is about 30KW, plus the oxygen price and sporadic consumables sponsored for cutting, the cumulative hourly usage price is as high as about 80 yuan. The system including cooling and charging covers an area of u200bu200bup to tens of square meters. The picture shows the working site of an imported five-axis laser machine tool. The combination of household robot + fiber laser is used for processing, trimming and punching, and other processes are completed at one time. The incision is neat and does not require subsequent processing. This greatly reduces the process flow, reduces labor costs and mold prices, and advances. Product grade and product added value.