Research on the application of laser cutting machine in the field of special vehicles

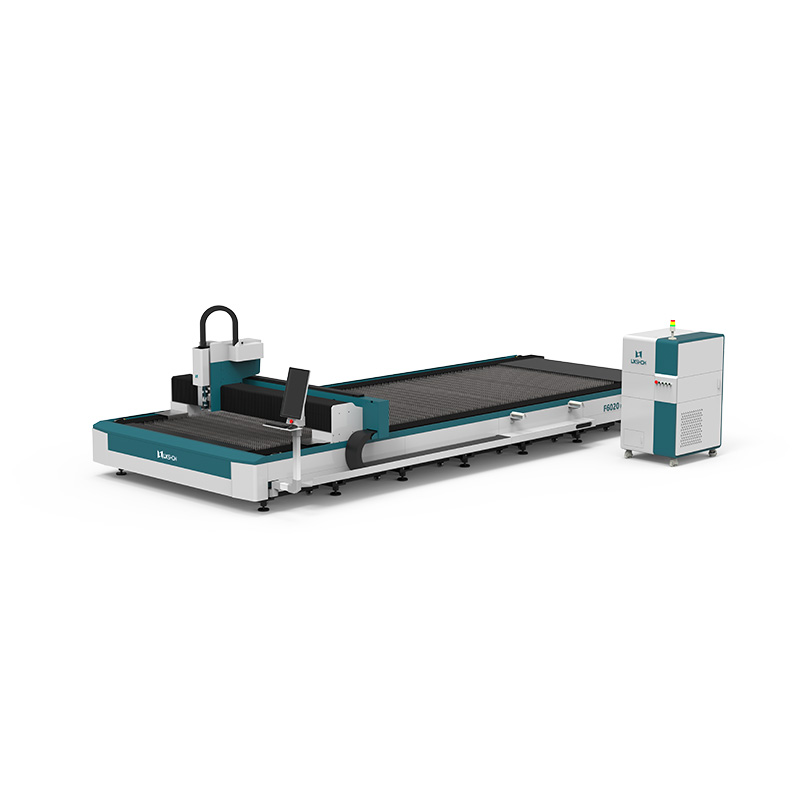

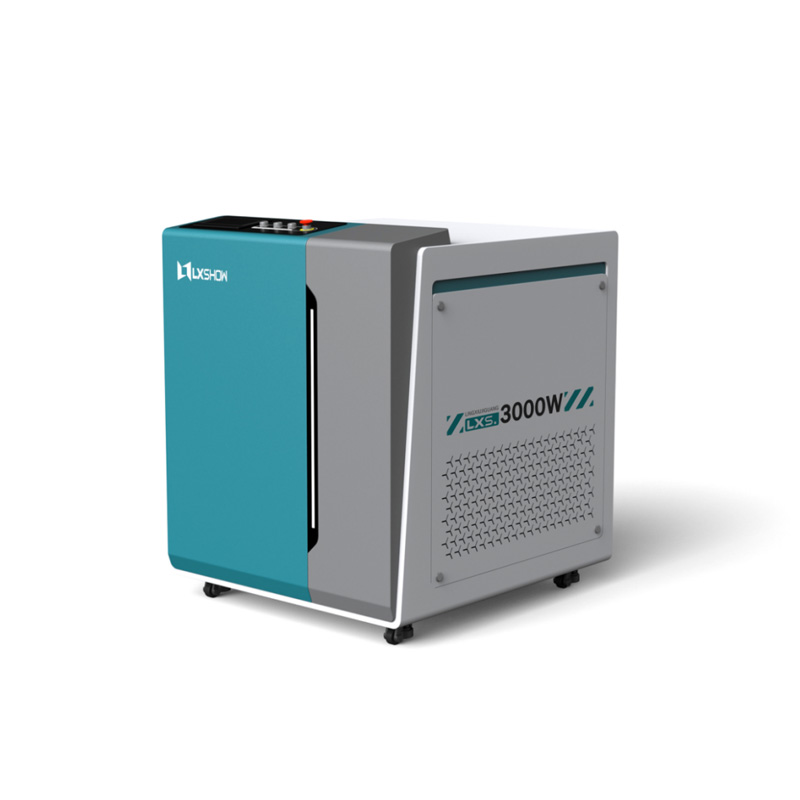

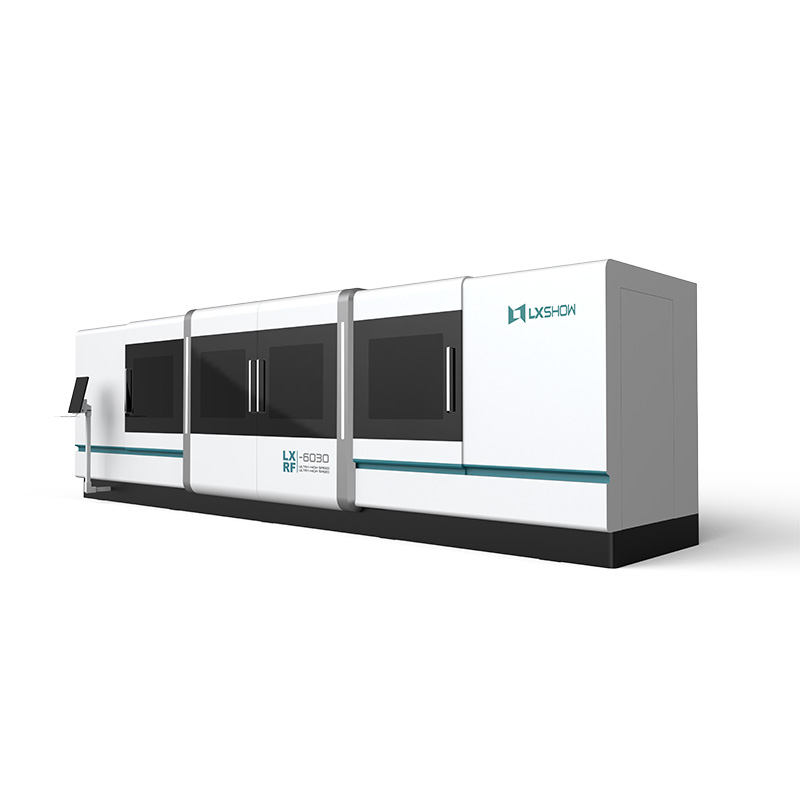

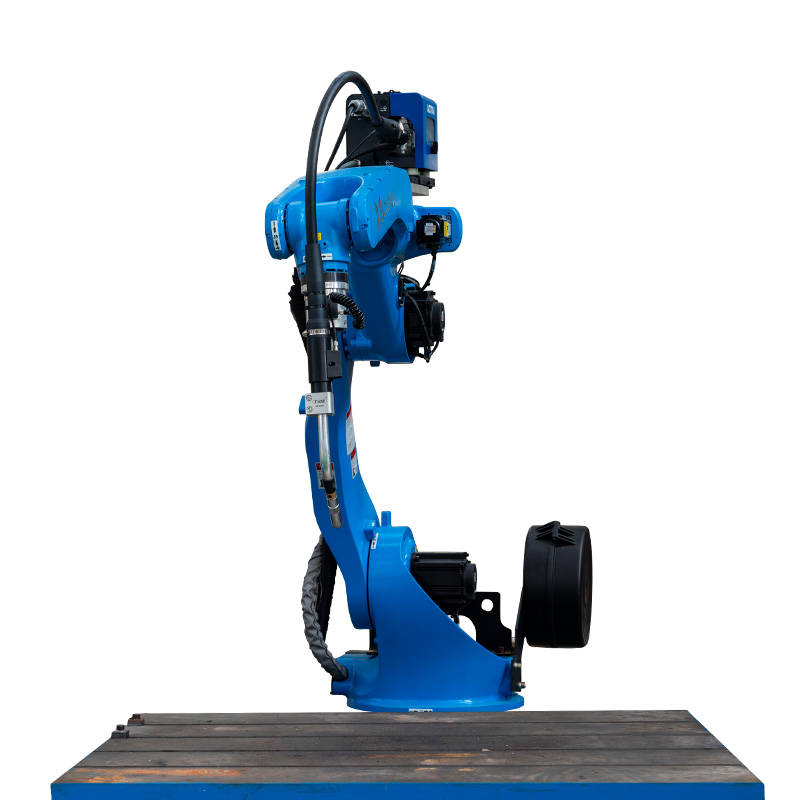

The fiber laser cutting machine uses a focused high-power density laser beam to irradiate the workpiece to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, it blows away the molten material with the aid of a high-speed airflow coaxial with the beam, thereby Cut the work piece apart. The application of fiber laser cutting machine in the production of special vehicles, what are the advantages compared with traditional processing technology. Laser processing technology is to pass a high-energy laser beam through a focusing optical system, so that the laser focus is irradiated to the surface of the material, using the thermal effect generated by the laser The technical method to realize the thermal processing of the workpiece. Due to its wide range of processing objects, high processing accuracy, fast processing speed and high efficiency, it has attracted the attention of domestic and foreign scholars since its inception, and has continuously developed in the field of industrial precision processing. Laser processing 3D curved surface needs to be realized by combining laser with advanced optical system and automation mechanism; its automation mechanism requires a multi-degree-of-freedom multi-axis configuration and a high advance stroke of the Z axis to meet the longitudinal processing depth and processing width of the workpiece. Spherical surface processing is the most common in 3D surface processing, and this kind of surface often requires the purchase of multi-axis laser precision machine tools for processing, which makes the manufacturing cost expensive.

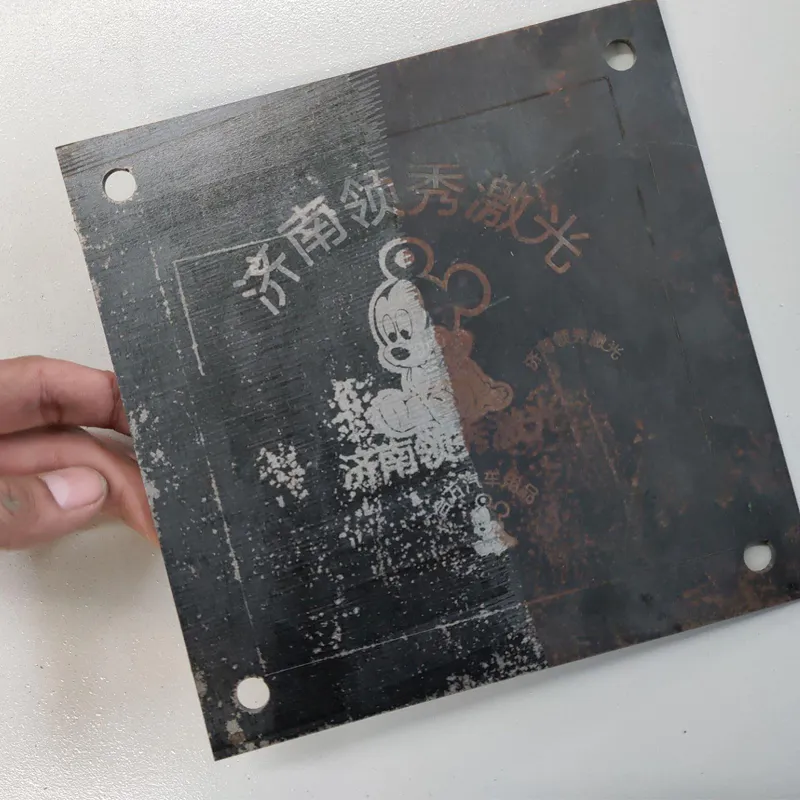

Therefore, this paper chooses a low-cost two-dimensional fiber laser cutting machine, draws lessons from the fractal digital mask theory in the production of binary optical devices, and performs three-dimensional high-frequency curved surface graphics. Step quantization obtains a series of graphic input sequences, which simulate spherical carving with low degrees of freedom. In addition, considering that the N-order fractal will make the quantized energy level once determined, the Z-axis advancement is required to eliminate the problems of insufficient laser cutting depth and low processing width accuracy caused by the defocusing cone effect. Based on the fractal theory, this paper proposes a dynamic fractal engraving method, that is, n (n According to the digital mask theory, the formation of a three-dimensional surface is determined by the laser energy distribution of the laser. For ordinary fiber laser cutting machines or engraving machines, once the laser energy level is determined, That is, I(x, y)u003dI is a fixed value, then the 3D surface depends entirely on the complex distribution of the residence time in the space coordinates. This kind of time distribution essentially requires a multi-degree-of-freedom automation mechanism to achieve, but it is precisely that ordinary fiber laser cutting machines do not have high-performance automation mechanisms, so fiber laser cutting machines generally can only achieve planar engraving based on graphic input and cannot be achieved. Three-dimensional curved surface is formed at one time. However, the fractal digital mask technology points out that high-frequency curved surface graphics can be quantized in N order to obtain N low-frequency fractal graphics. The total laser energy distribution expression is the product of dwell time and the corresponding low-frequency fractal light intensity distribution In fact, since N cannot approach infinity, there must be quantization errors in processing. For the spherical surface, there are generally equidistant quantization and contour quantization. Quantify the geometric relationship of the spherical crown. For equidistant quantization, it requires different step heights, which means that the N image input has different laser energy levels and long-term test values, and the stepped spherical surface error obtained is larger. . Because fractal processing usually has only one quantized energy level, it still needs Z-axis long-range advancement. Otherwise, due to the limitation of processing depth, only small-size spherical parts can be produced, and laser The tapering effect after defocusing has an impact on the line width accuracy, so the radius of the annulus needs to be properly compensated according to actual tests. In addition, if the spherical graphics use N input graphics, the center of the circle may not coincide well in the actual processing process, that is, there is a cumulative calibration error that affects the appearance of the spherical processing; therefore, the dynamic fractal method is used to propose nu003dlog2N fractal graphics for processing Spherical. The fractal graphics method is used to quantify spherical parts, which provides a new low-degree-of-freedom processing method for spherical laser processing, and at the same time provides a possible solution for 2D ordinary fiber laser cutting machine to achieve 3D spherical molding. Research shows that the large number of quantization steps N in the fractal graphics method means that the number of input graphics is large, and the step depth Δh is small, which will affect the aging and processing accuracy.