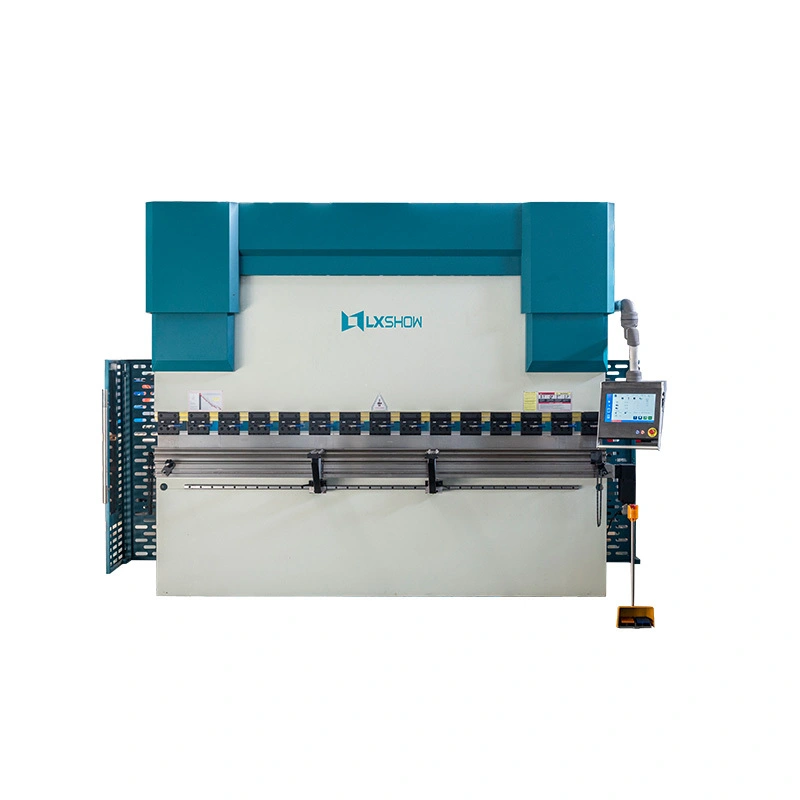

Metal Press Brake Electro-hydraulic Bending Machine WE67K 160T-3200mm Delem DE15 System

- Model Number:WE67K

- Lead time:15-25 working days

- Payment Term:T/T;Alibaba trade assurance;West Union;Paypal;L/C.

- Brand:LXSHOW

- Warranty:3 years

- Shipping:By sea/By air/By Railway

DE 15 System

1. Support switching between angle programming and depth programming

2. Support mold library product library settings

3. The opening height can be set freely for each working step

4. The shift point position can be freely controlled

5. Standard Y1, Y2, R and other multi-axis expansion

6. Support mechanical compensation table control!

7. Support large arc automatic generation program!

8. Support top dead center, bottom dead center, loose foot, delay and other step-changing options, effectively improving processing efficiency

9. Support electromagnet simple bridge

10. Support the function of fully automatic pneumatic dragging bridge

11. Support automatic bending, realize unmanned bending control, and support automatic bending of up to 25 working steps

12. Support valve group configuration function, fast down, slow down, return, unloading action and valve action time control

Concentric CNC Mould

1. The upper die adopts heavy-duty clamping T-slot.

2. The upper and lower molds adopt segmented short molds, and the length required for splicing has high precision and good interchangeability, and is easy to disassemble. The connecting part is equipped with a compensation mechanism to compensate the deflection of the worktable and the slider when bending the sheet to ensure high working accuracy.

3. The lower mold is processed into different "V"-shaped grooves for easy selection by the operator, and it is equipped with a lower mold turning mechanism. Just put the lifting chain on the slider lug and the lower mold lug, loosen the top mold to lift The slider can rotate the lower die to select the required "V" groove position surface.

Wear-resistant Quick Clamp

The inner side of the CNC quick fixture is equipped with wear-resistant rubber strips, which are easy to clamp when installing the bending machine mold, without loosening, and do not drop the tool, which greatly shortens the adjustment time for clamping the upper mold.

Front bracket

1.Placed on the side of the workbench and fixed by screws.

2.It can be used as a place when bending wide and long sheets.

Compensational Convex Workbench System/Mechanical Compensation

1. The compensation system is a CNC axis that controls the convexity of the worktable, and can obtain accurate deflection compensation on the entire length of the worktable.

2. The convex workbench is composed of a group of convex wedges with slopes: each convex wedge is designed and processed according to the deflection curve of the slider and the vertical plate of the worktable through finite element analysis;

3. The numerical control system calculates the required compensation amount according to the load force when the workpiece is bent (this force will cause deflection and deformation of the slider and the vertical plate of the workbench), and automatically controls the relative movement of the convex wedge, so as to effectively The deflection deformation produced by the slider and the table is perfectly compensated, and the ideal bending workpiece can be obtained

Back barrier

1. The adjustment of the back gauge is driven by a servo motor.

2. The rear gauge screw is positioned by a precision ball screw and supported by a linear guide.

3. H-type synchronous belt synchronous wheel transmission, high transmission precision, low noise.

Slide

1. Up-moving bending design, low noise and stable working condition;

2. The guide rail surface of the slider is equipped with a self-lubricating guide plate made of wear-resistant materials;

3. The slider and the oil cylinder are rigidly connected to better ensure the synchronization accuracy requirements of the slider in the fast forward, work forward and fast return states.

Distribution box

1. The electrical components are imported from abroad or joint venture products, conforming to In line with international standards, safe and reliable, long life, anti-interference performance strong;

2. Movable button station (including foot switch), convenient operation, with emergency stop function;

3. The working system must have necessary limit protection measures. Once an abnormality occurs, it should be able to detect through the system and give an alarm immediately. Motor overload and short circuit protection adopts automatic air switch; there is short circuit protection of control circuit; all "emergency stop" buttons are interlocked, press any one, the machine tool will stop.

Foot switch

1. Improved convenience and efficiency of operation: The operator can control the start, stop or jog operation of the machine by foot, freeing his hands and allowing him to focus on positioning, supporting and adjusting the workpiece.

2. Industrial-grade design: The foot switch of the bending machine usually adopts a design with high mechanical strength and current resistance, which can adapt to harsh industrial environments and is durable.

3. Easy to maintain: A well-designed foot switch, such as modular components, can simplify maintenance and replacement and reduce maintenance costs.

Siemens Main motor

1.Servo motors are high quality, innovative and efficient.

2.The motor family incorporates more than 150 years of Siemens experience and is an important element of Siemens' Digital Enterprise solutions.

Mechanical Servo Bending Help

1.When mark bending support plate can realize the function of turning over following.following angle and speed are calculated and controlled by CNC controller,move along linear guide left and right.

2.Adjust the height up and down by hand, front and rear can also be adjust manually to suit for different bottom die openning.

3.Support platform can be brush or stainless steel tube ,according to workpiece size,two supports linkage movement or seperate movement can be chosed.

Laser Safety Guard

1.Lasersafe PSC-OHS safety guard, communication between CNC controller and safety control module.

2.Dual beam from protection are point below 4mm below the tip of upper tool,to protect operator`s fingers.

3.Three regions(front,middle and real) of leaser can be flexibly closed,ensure complex box bending processing ;mute point is 6mm,to realize efficient and safe production.

Sealed security door

1. Protect operators from splashing objects: The type with a transparent observation window can effectively block splashing objects and protect the eyes and body of operators while providing convenient observation.

2. Reduce noise and dust: It plays the role of sound insulation and dust blocking, improving the working environment.

Safety Side Guards

1. Prevent contact with hazardous areas: The side guards act as a physical barrier that effectively blocks people from entering these hazardous areas from the side and avoids accidental contact.

2. Prevent hand injuries: Prevent the operator's hands from reaching into the machine and touching the moving back gauge or other parts that may cause injury.

3. Cooperate with the overall safety system: The side guards work together with other safety equipment such as light curtains and interlocks to form a more comprehensive protection area.

Technical Parameters

|

Machine model |

WE67K-160T/3200 |

|

|

Nominal Pressure |

1600 kN |

|

|

Bending length |

3200 mm |

|

|

Distance between columns |

2600 mm |

|

|

Throat Depth |

330 mm |

|

|

MAX Pressure of system |

22 Mpa |

|

|

Slide running condition

|

moving journey/stroke |

200 mm |

|

fast down speed |

180mm/s |

|

|

return speed |

110mm/s |

|

|

working speed |

10mm/s |

|

|

Slide running precision

|

Position accuracy |

±0.03mm |

|

Repeat Position accuracy |

±0.02mm |

|

|

Main motor power |

Power |

11 KW |

|

rotate speed |

1440 r/min |

|

|

Operate system |

Model |

DE15 |

|

Oil Pump |

Model |

USA sunny |

|

Bending precision |

angle |

±30' |

|

straightness |

±0.7mm/m |

|

|

Voltage |

220/380/420/660 V |

|

| Tech Info |

1)Tonnage=8*1.68*stainless Steel thickness*plate Width 2)Tonnage=8*carbon steel plate thickness*plate width |

|

|

Package size |

3600(length)*2080(width)*2740mm(height) |

|

|

Machine Weight |

8 T |

|

Mold Display

Bending sample display

Quality Inspection

Application of electro-hydraulic bending machine

Electro-hydraulic bending machines are widely used in the metal processing industry, mainly used to bend metal sheets into various shapes, suitable for the fields of automobiles, aerospace, ships, metallurgy, etc. For example, in aerospace, bending machines are used to manufacture aircraft parts; in automobile manufacturing, they are used to produce body structural parts; in shipbuilding, they are used for bending processing of hull structures.

FAQ

Q: If we are interested in your machine, how do we choose?

1. What main job you do with the machine? We can make different molds according to your different needs

2. What is your request max working area? __mm* __mm?

3. What's your material thickness & length?

4. What material you want to bending?

Please tell us, then we can recommend the suitable machine to you.

Q: What are the differences between the three types of machines? Which one should I choose?

We have 3 models bending machine for your choice.

1 Electro Hydraulic bending machines

2 efficient bending machines

3 simple bending machine.

The work efficiency is 1>2 >3. also the price is a 1>2>3.

if you can’t confirm, We will quote 3 kinds, then you can choose according to your budget.

Q: How about warranty?

A: We support 3 years warranty,when you have any questions, you cancontact us anytime.

Q: How about your after-sales service?

A: We have a 24-hour professional after-sales service team, which can provide online and offline after-sales service, and we can provide door-to-door service if you need it.