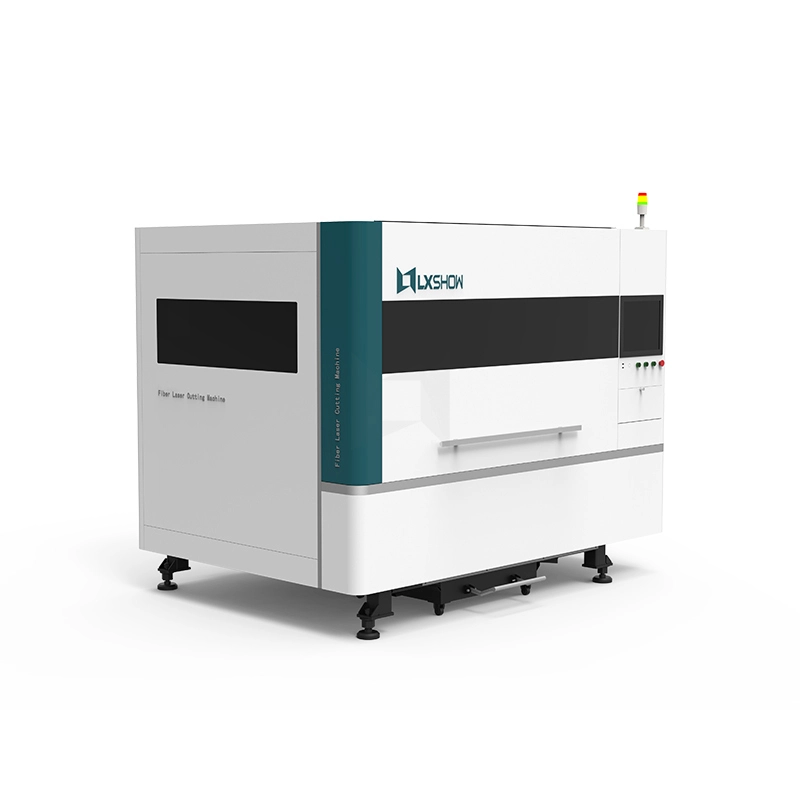

Fully Enclosed Small-Format Professional laser cutting machine LX1390M Series for Sale

Machine Weight:2200KG

Machine Size:2110*2724*2021mm

Lead time:10-15 working days

Brand:LXSHOW

Warranty:3 years

Payment Term:T/T;Alibaba trade assurance;West Union;Paypal;L/C

Strong Stability, High Precision, 20 Years Without Deformation

Using carbon structural steel, the surface is smooth, wear-resistant, heat treatment, stress annealing, and vibration treatment eliminate the stress generated during the welding and processing of the machine bed, and the machine tool accuracy is long-lasting.

Double guide rail and double drive design

To prevent the Y-axis lead screw from bending and causing deformation of the cutting line, the Y-axis on both sides adopts a double guide rail and double drive lead screw design to ensure straightness and arc during high-speed cutting.

Cast aluminum beam

The beam has good integrity, rigidity, surface quality, toughness and toughness after artificial aging, solution treatment and fine machining. The metal characteristics of aluminum alloy are light weight and high hardness, which is conducive to high-speed movement in processing, high flexibility, and high-speed cutting of various graphics on the basis of high precision.

Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.