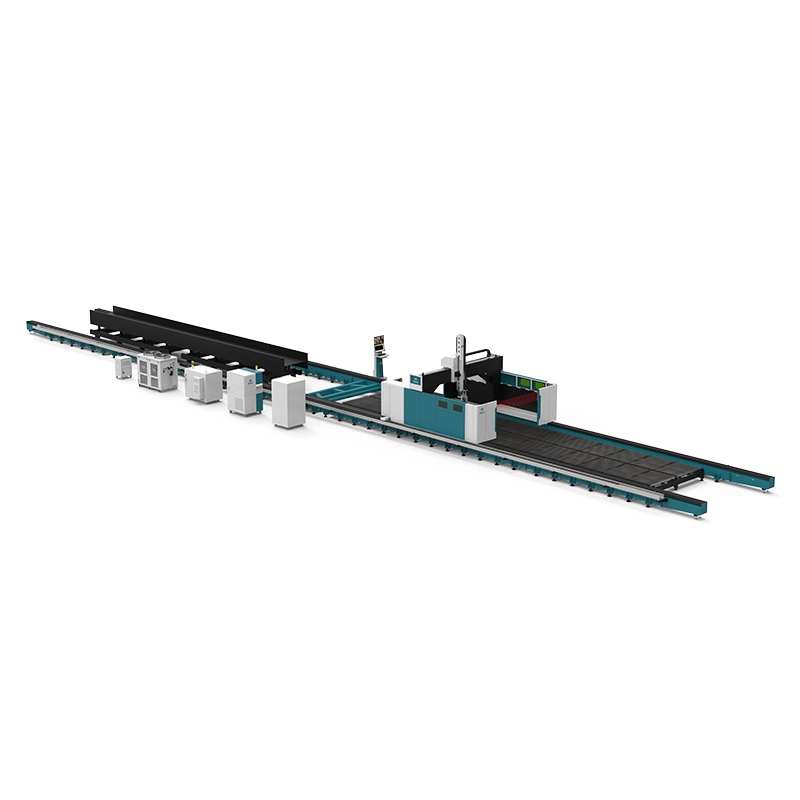

LX16016TGB H-shaped steel fiber laser cutting machine

LX16016TGB

Fast, clean cuts on various profiles (I-beam, channel, angle). Boost efficiency & reduce waste in steel construction, engineering machinery, and more. Automated loading/unloading options. Contact us for advanced solutions!

Model Number:LX26016TGB

Warranty:3 years

Shipping:by sea/ by land

Payment Term:T/T;Alibaba trade assurance;West Union;Paypal;L/C

Lead time:25-40 working days

Brand:LXSHOW

Warranty:3 years

Shipping:by sea/ by land

Payment Term:T/T;Alibaba trade assurance;West Union;Paypal;L/C

Lead time:25-40 working days

Brand:LXSHOW

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Advantages

- High-precision cutting: Laser cutting has extremely high precision and can achieve cutting of complex shapes and precise sizes, ensuring the quality of H-beam components.

- Fast cutting speed: Compared with traditional cutting methods (such as flame cutting and plasma cutting), laser cutting is faster, significantly improving production efficiency and shortening construction period.

- High cutting quality: Laser cutting cuts are flat, smooth, and burr-free, reducing or even eliminating secondary processing, saving labor and costs.

- High degree of automation: Professional H-beam laser cutting machines are usually equipped with functions such as automatic loading and unloading, automatic measurement, and automatic cutting to achieve one-stop automated operations, reduce manual intervention, and reduce labor costs.

- High material utilization: Laser cutting uses a fine cutting path to optimize material arrangement and reduce material waste. Some equipment also has the functions of automatic splicing of excess materials and short tail cutting to further improve material utilization.

- Flexible processing: Laser cutting can quickly switch to cut different shapes and sizes through programming, which is suitable for diversified and customized H-beam component processing needs.

- Reduce thermal deformation: The heat-affected zone of laser cutting is small, which reduces the risk of deformation of H-shaped steel during cutting and ensures the accuracy of components.

- Environmental protection: Compared with traditional cutting methods, laser cutting produces less dust and noise, which is more environmentally friendly.

- Precision calibration and compensation function: Some advanced equipment has the function of steel precision calibration and compensation, which can automatically detect and compensate for the error of steel and ensure the accuracy of cutting size.

Good reasons for working with us

The target market of our brand has been continuously developed over the years. Now, we want to expand the international market and confidently push our brand to the world.

Mature global export network

LXSHOW Laser's equipment is sold to countries around the world, which clearly demonstrates its good performance record and mature international trade channels. This global layout simplifies the logistics, customs clearance process and after-sales support for overseas customers.

Commitment to the Laser and Sheet Metal Processing Industry

By focusing on laser technology and related sheet metal processing equipment (bending, shearing), LXSHOW Laser demonstrates specialized knowledge and a deep understanding of the specific needs of this sector in the global market. This specialization can lead to more innovative and competitive product offerings for international customers.

Extensive 21 Years of Manufacturing and Sales Experience

Founded in 2004, LXSHOW Laser possesses over two decades of valuable experience in the laser equipment industry. This longevity demonstrates stability, accumulated expertise in production processes, and a deep understanding of market demands, fostering trust with international buyers.

In-House Manufacturing and Sales Expertise

Being a manufacturer with its own sales operations provides LXSHOW Laser with greater control over product quality, pricing, and customer service throughout the entire export process. This direct involvement can lead to more efficient communication and tailored solutions for international clients.

Professional H-beam laser cutting machines are widely used in the following industries and fields

- Steel structure buildings: used to cut various H-beam components such as steel beams, steel columns, purlins, supports, etc., and are used in steel structure projects such as industrial plants, high-rise buildings, bridges, stadiums, airports, and stations.

- Engineering machinery: used to cut structural parts of engineering machinery such as cranes, excavators, and loaders.

- Power facilities: used to cut H-beam components of power facilities such as electric towers and substation frames.

- Shipbuilding: used to cut H-beam components in hull structures.

- Road and bridge transportation: used to cut H-beam components of transportation infrastructure such as bridges, tunnels, and elevated roads.

- Marine engineering: used to cut structural parts of marine engineering such as offshore platforms and oil drilling platforms.

- Storage shelves: used to cut H-beam components such as shelf columns and beams.

- Other metal processing industries: all industries that require cutting, punching, beveling, and other processing of H-beam and other profiles

Aerospace Industry

Automotive Manufacturing

Construction Machinery Industry

Electronics Industry

Fitness Equipment Industry

Handicraft industry

Hardware industry

Shipbuilding Industry

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

contact us for a quote!

Please tell us which product you want to know or your production needs, we will choose the most suitable machine for you!

Service staff

Related Products

no data

E-mail : enquiry@lxshow.net

Mobile / Whatsapp / Wechat:

+86-15610137252

Address: Golden Age Plaza, Block A, No. 9999 Jingshi Road, Lixia District, Jinan City, Shandong Province