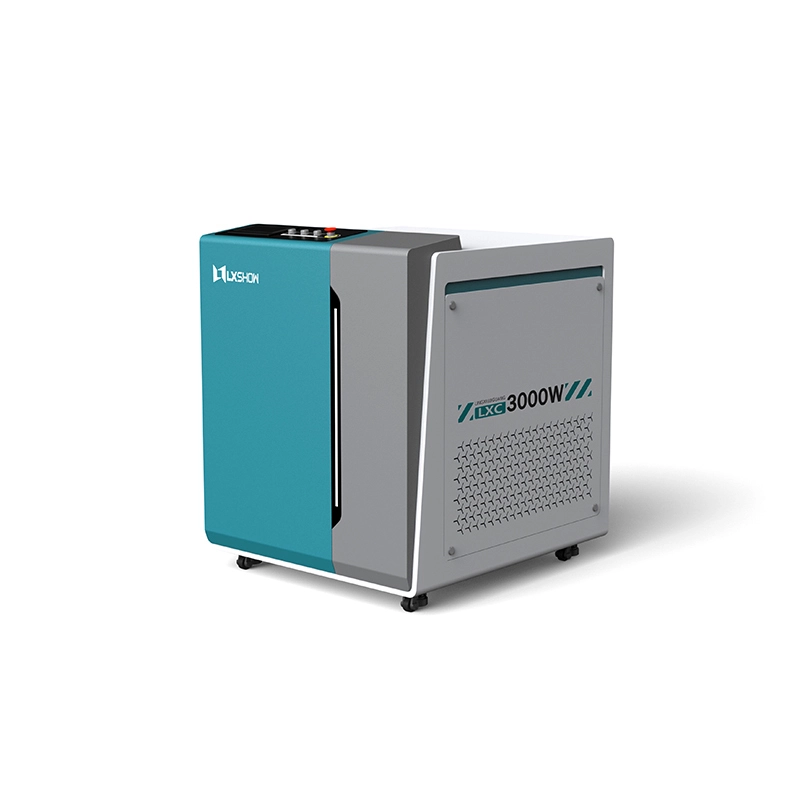

Laser Cleaning Machine 3000W With Built-in Water Coller, Portable, Affordable And Practical Fiber Laser Cleaning Machine

Model Number: LXC-3000W

Lead time: 7-15 working days

Machine weight: 392KG

Warranty: 2 years

Shipping: By sea/By air/By Railway

Payment Term:T/T: Alibaba trade assurance;West Union;Payple;L/C.

Application: Remove rust, paint, oil, resin, dirt, and oxidized coatings from metal, wood, and stone surfaces

Laser cleaning machine Features

1. Simple interface operation

2. No chemical required, safe and environmentally friendly

3. High efficiency, saving time

4. Hand-held design is easy to carry

5. No damage to parts

6. Quick setup

7. No additional consumables are generated during cleaning

How laser rust removal tool work

1. Powerful, very short, rapid and moving laser pulses produce micro-plasma bursts, shock waves and thermal pressure resulting in sublimation and ejection of the target material.

2. A focused laser beam precisely vaporizes the target coating or contaminant.

3. Process optimization of the laser beam produces maximum reaction with the target material for speed while, at the same time,does so safely and without harm to the base material.

4. Laser beam power density is accurately and easily adjusted to achieve cleaning results impossible with all other options.

CNC Control System

1、With clear and simple interface page

2、Various parameters can be set by yourself

3、Automatic operation: stable cleaning,high efficiency

4、No need chemical cleaning liquid: no consumables

Creativity & Design

Advantages:

1.Stable system and low operating cost

2.No need for tedious maintenance and repair

3.The most environmentally friendly industrial cleaning method

4.Portable dust auxiliary treatment system (optional)

Tips:

1. As a consumable part of the cleaning machine, the protective lens has a service life of about 500 hour. You can choose some protective lenses as an option when you purchase the machine.

2. Laser cleaning machine support language:Chinese(Simplified/traditional), English, Japanese, Korean, Russian, Spanish, Greek and French.

Application:

Rust Removal Portable Fiber Laser cleaning machine can remove the object surface resin, the paint, the oil pollution, Stains, dirt, rust, coatings, coatings and oxide coatings are widely used in the industry, covering ships, steam repairs, rubber molds, high-end machine tools, track and environmental protection.