High Power LX12025P Fiber Laser Cutting Machine Double Table Full Cover Heavy Bed

- Machine Model:LX12025P

- Power of Generator:3000-40000W

- Dimension:27411*4320*2765mm

- Working Area:2500*12000mm

- Repeated Positioning Accuracy:±0.02mm

- Max Running Speed:160m/min

- Max Acceleration:2G

- Specified Voltage And Frequency:380V 50/60HZ

Advantages of the LX12025P Fiber Laser Cutting Machine

1. Extremely High Productivity

The automatic table exchange is its core advantage. While a sheet is being cut on one table, the operator can load or unload a new sheet on the other table. After the cut is complete, the two tables quickly and automatically swap, virtually eliminating waiting time for loading and unloading, minimizing non-productive time.

2. High Safety

The fully enclosed design not only effectively protects the operator from laser injuries and fume hazards, but also contributes to a cleaner and more environmentally friendly working environment.

3. Large-Format Material Processing Capability

The large-format table easily handles oversized metal sheets, improving cutting accuracy and efficiency while significantly reducing material waste.

4. High Precision and Stability

The LX12025P utilizes fiber laser technology, combined with a highly rigid chassis and high-precision transmission components, to ensure exceptional cutting accuracy and stability.

Machine Model | LX12025P |

Power of Generator | 3000-40000W |

Dimension | 27411*4320*2765mm |

Working Area | 2500*12000mm |

Repeated Positioning Accuracy | ±0.02mm |

Max Running Speed | 160m/min |

Max Acceleration | 2G |

Specified Voltage And Frequency | 380V 50/60HZ |

Monitoring system

Real-time observe the machine running through the panel

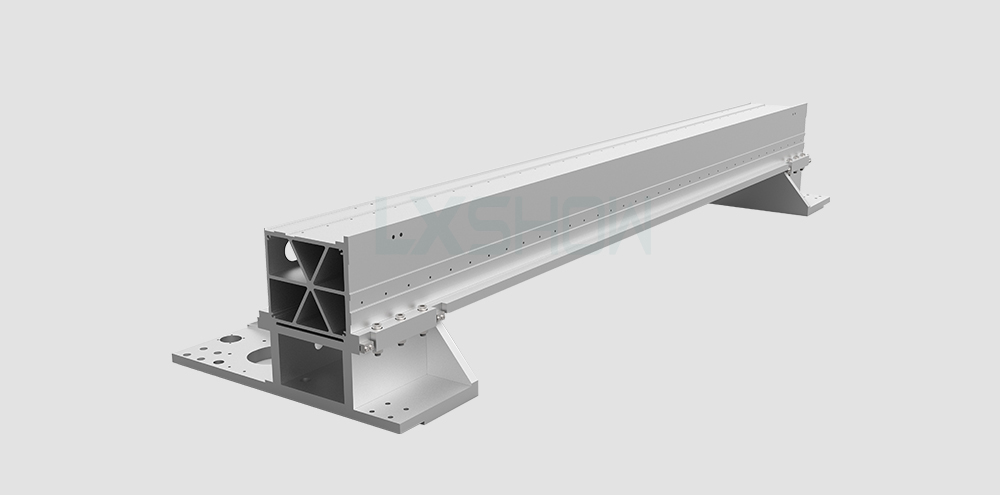

Brand New Cast Aluminum Beam

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Independent Control Cabinet

Dust-proof

•All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

•The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

High-performance plate welding bed

1.Heavy-duty plate welding hollow bed, small thermal deformation and stable machine.

2.The whole machine has three layers of protection, graphite plate, copper plate and fire-proof brick to prevent the bed from being deformed by heat.

3.The middle of the platform is connected by a 30mm thick plate and protected by a graphite plate to prevent the deformation of the high-power platform caused by cutting and insufficient load-bearing.

4.The platform frame adopts the overall frame + small grouping design, which improves the bearing capacity of the platform and facilitates later maintenance and replacement.

Intelligent Autofocus

The high efficiency cooling:

Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.

Chase the light aperture:

Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.

Automatic focus:

Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.

High speed cutting:

25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.