Hard standards for choosing metal laser cutting machines.

Due to the need for production work, many companies need to process products through metal laser cutting machines. For manufacturers who do not have metal laser cutting machine equipment, they need to buy a suitable metal laser cutting machine. So how can we choose a suitable product? Is there any standard? Let's take a look.

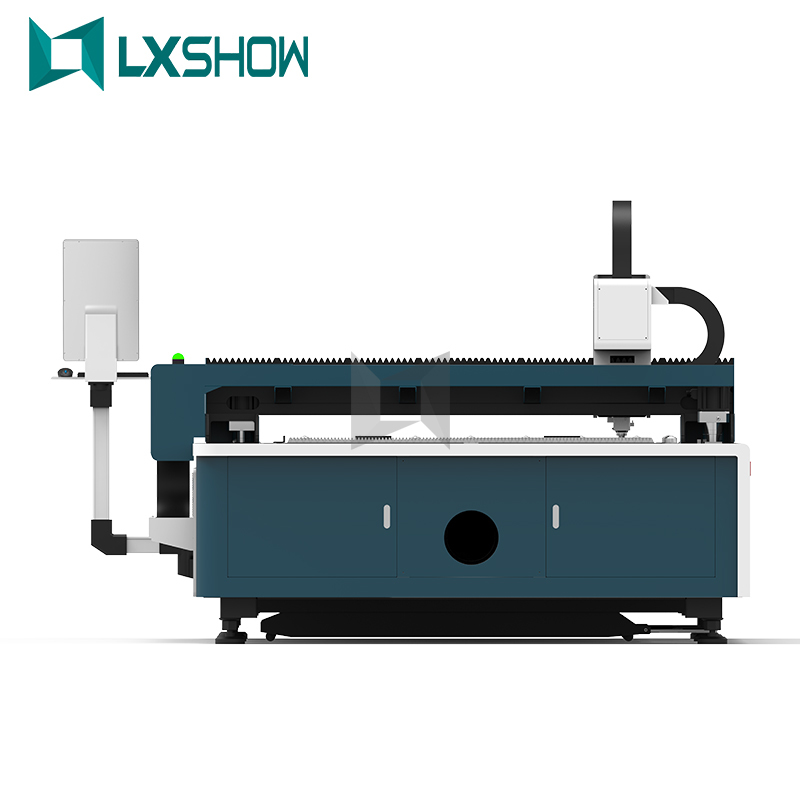

Metal laser cutting machine is a kind of cutting machine that uses the principle of laser to illuminate the laser on the metal surface, vaporize the metal with high temperature, and then liquefy it with gas. The cutting head of this model will walk according to the programmed trajectory, and the cut is very good at this time. We all know that the distance between the cutting nozzle of the cutting machine and the surface of the workpiece is the most critical factor that determines the quality and speed of the cutting opening.

For buyers, depending on the types of products processed or manufactured, coupled with different material widths and different processing thicknesses, the requirements for lasers are different, and the core of the laser cutting machine is also the most expensive. The place. The power of the selected laser is different, and the price of the laser cutting machine is also different.

Generally speaking, high-power laser cutting machines can better process thick plates, while fiber laser cutting machines are more suitable for processing thin plates. In this case, the price of different metal laser cutting machines is naturally different according to the material parameters you are processing and producing. Therefore, you can't just look at the price of the metal laser cutting machine, you must purchase the metal cutting machine according to the equipment parameters that meet your needs.