How to promote the development of metal laser cutting machine application technology?

In today's metal sheet metal processing research institute, especially in recent years, many excellent processes have been continuously used in metal laser cutting machine equipment, which has strengthened the inherent functions of laser cutting equipment in China and improved the stability of internal performance. In the industry, laser equipment is of great significance in various manufacturing industries. The metal laser cutting machine can cut quickly and easily, and can quickly produce various complex shapes, which is deeply loved by decoration companies.

As long as the customer needs, make graphics through computer-aided design, and then provide relevant information, you can cut immediately, even if the customer requires a custom mode, there will be no difficulties in use. The metal laser cutting machine equipment is undergoing multiple transformations. The manufacturing design has developed a new high-tech, metal laser cutting machine manufacturing company to ensure that the cutting process of many products is the key to environmental protection. Otherwise, the pollution is not only the working environment but also the product loss caused by the powdery waste that is difficult to clean. Necessary Losses, and labor repairs at the same time, are huge losses caused by small losses.

Simply put, sheet metal processing is the cutting of various plates and various graphic parts. The advantages of metal laser cutting machines have been fully utilized in this industry, saving time and energy, high cutting precision, fewer materials, and can be processed and used. The sheet metal industry should be the industry that uses the most metal laser cutting machines, and transmits energy through flexible integrated optical fibers, without the need for lens or optical calibration or adjustment.

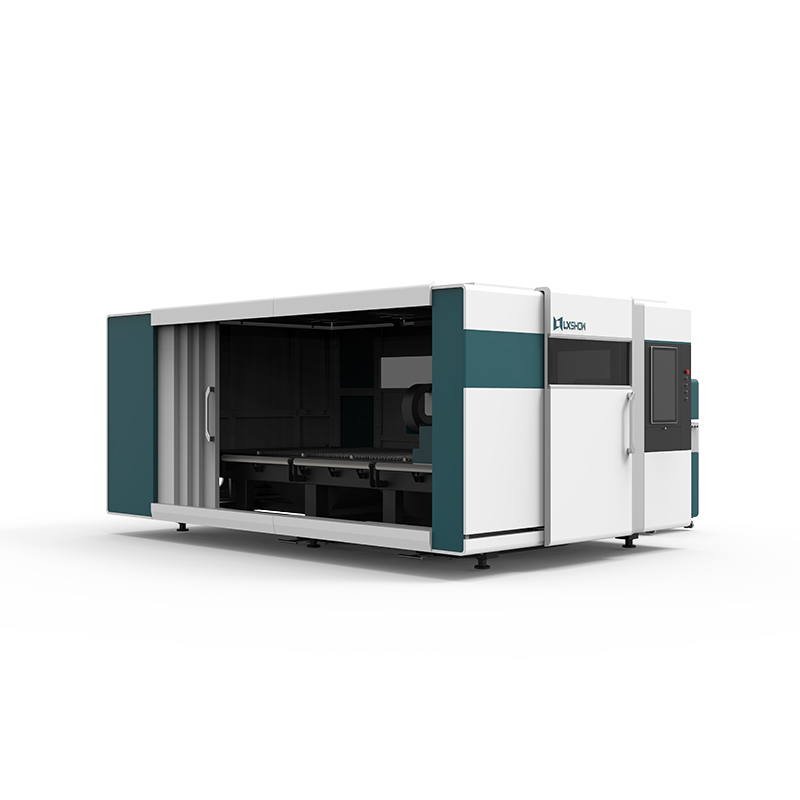

The new metal laser cutting machine is smaller and lighter than the traditional cutting machine, which saves installation space. In addition, the traditional laser cutting machine uses the lens for precise collimation. Pay attention to the application. The fiber laser cutting machine has a stronger structure and is It runs well in the working environment, and the transportation process is more convenient and safer.