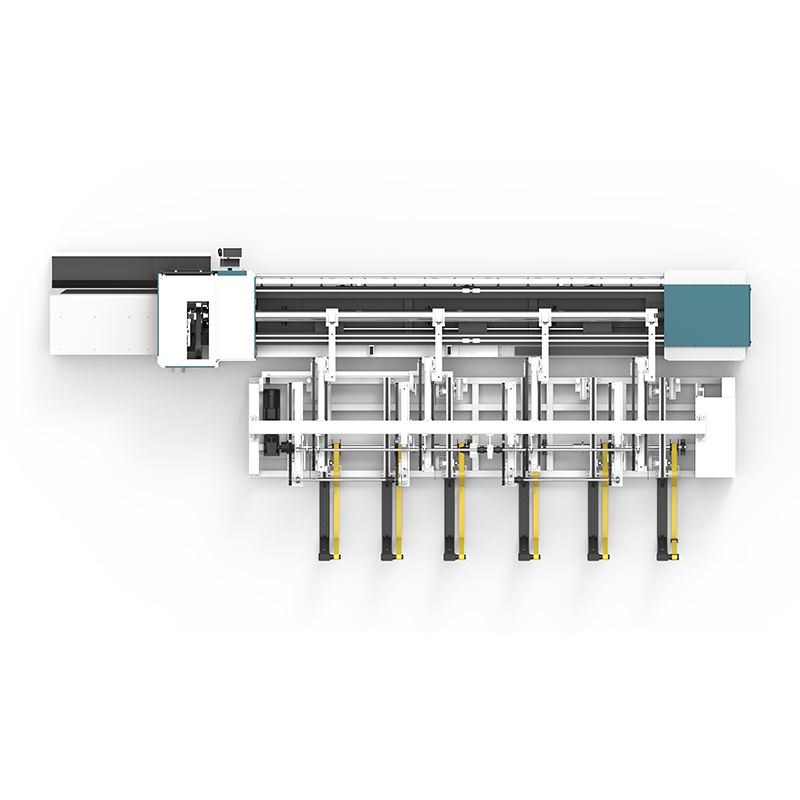

Application range and technical advantages of automatic laser pipe cutting machine

A metal tube laser cutting machine is also called an automatic laser tube cutting machine. Different from other small fiber laser cutting machines, tube fiber laser cutting machine is specialized and can only be used to cut metal steel pipes. We all know that it is relatively simple to cut metal steel pipes, but it is very difficult to punch holes or cut patterns on the pipe wall, requiring superpower and processing width. Tube fiber laser cutting machines mostly use Raycus fiber lasers, which have a very strong ability to cut metal, and the metal has a very good absorption effect on this laser tube. Therefore, for the cutting of metal steel pipes, pipe laser cutting machines are indispensable tools. Let us take a closer look at the product features, application scope, and technical advantages of the tube automatic laser tube cutting machine.

1. Product features

1.1 Chuck configuration

The main chuck is a pneumatic or electric clamping chuck, with two independent cylinder power sources built in to drive the jaws to realize the two-by-two linkage and self-centering of the four jaws without mutual interference.

For the special-shaped pipe material, no adjustment operation is required, and the special-shaped pipe can be clamped by the movement of the claw block.

The rear chuck is a Zhongshi pneumatic clamping chuck, which can clamp and clamp the workpiece according to the shape of the pipe to meet different requirements.

Advantages of chuck:

Increase jaw stroke, no need to adjust jaws if the pipe diameter changes within 100mm

The self-adjusting center of the chuck automatically adjusts the tightening force according to the profile specifications to ensure that the thin tube is clamped without damage.

1.2 Cutting nesting software

⊙Support real-time deviation compensation of the tube core, reduce the clamping requirements of the tube, and greatly improve the progress of the perforation.

⊙Support angle steel and channel steel cutting, set a separate corner process to improve the speed and quality of corner-cutting.

⊙Support real-time feedback of encoder, adding error measurement tools to facilitate obtaining the best motion parameters of the machine tool.

2. the scope of application

The automatic laser pipe cutting machine is widely used for cutting various metal pipe materials with high precision, such as the familiar nickel-molybdenum alloy, alloy steel, stainless steel, carbon steel, titanium, copper, aluminum and alloys. Therefore, the tube laser cutting machine is the best choice for cutting various thick metal tubes.

3. Technical advantages

3.1 The machine adopts gantry structure, imported rack and high-precision linear guide, stable transmission, high precision, advanced optical design scheme is stable and efficient, greatly improving the production efficiency of the cutting machine.

3.2 The bed and beam adopt an integral welded structure, which is annealed at high temperature and two-time aging. The large gantry milling machine is processed into a one-time process. It has good rigidity, high precision, and can be used for a long time without deformation.

3.3 The X, Y, Z, and rotating axes all adopt high-precision servo motors, with stable and durable performance. Ensure the high speed and acceleration of the whole machine.

3.4 It adopts cypCUT numerical control system based on Windows operating system, special control system for laser pipe cutting machine, and integrates many special function modules for laser pipe cutting control. It has powerful functions, good man-machine interface and simple operation. This system is the core technology of CNC cutting machine to realize "full-time cutting, high-efficiency cutting and high nesting rate cutting", and it is the fundamental guarantee for effectively saving materials and improving cutting efficiency.

3.5 The cutting head adopts a special single focal length cutting head for fiber laser tube cutting and a capacitive sensor, which has high sensing accuracy, sensitive response, and the most stable and reliable performance.

3.6 Imported high-precision electric control air valve can precisely control the air pressure of cutting auxiliary gas to achieve the best cutting effect.

3.7 In the pipe cutting chuck part, the numerical control system uses the highly sensitive capacitive patrol principle to automatically find the center position of the pipe and automatically center it. The one-piece structure makes cutting easier. Quickly locate the center of various special-shaped pipes, eliminating the tedious and low precision of manual searching. The use of front and rear dual-drive synchronous rotation mode solves the problems of tube distortion and cutting deformation caused by single-active rotation in the traditional industry. The chuck adopts a large stroke, which avoids the trouble of frequently adjusting the chuck every time different pipes are cut.

3.8 The automatic material support system adopts the cylinder driving method to ensure that the pipe does not bend and maintains horizontal precision cutting in real time.