The operation of the fiber laser cutting machine can actively clamp the material

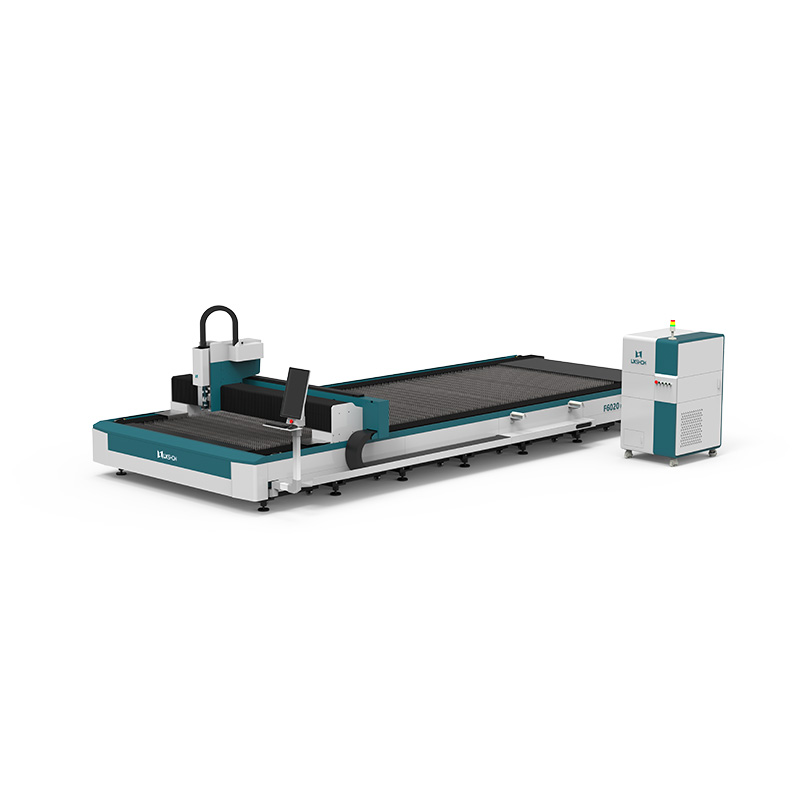

The type of fiber laser cutting machine is better for cutting materials. When we make the cutting machine, we usually divide into three models, large, medium and small. The small model is for a few relatively small tubes. Pipes or pipes are planned. Because they are relatively small, the pipes cut out are smaller and lighter. Even if they fall naturally, they will not have any impact and will not damage the product, like this model. , Let's just let it liberate and blank the material.

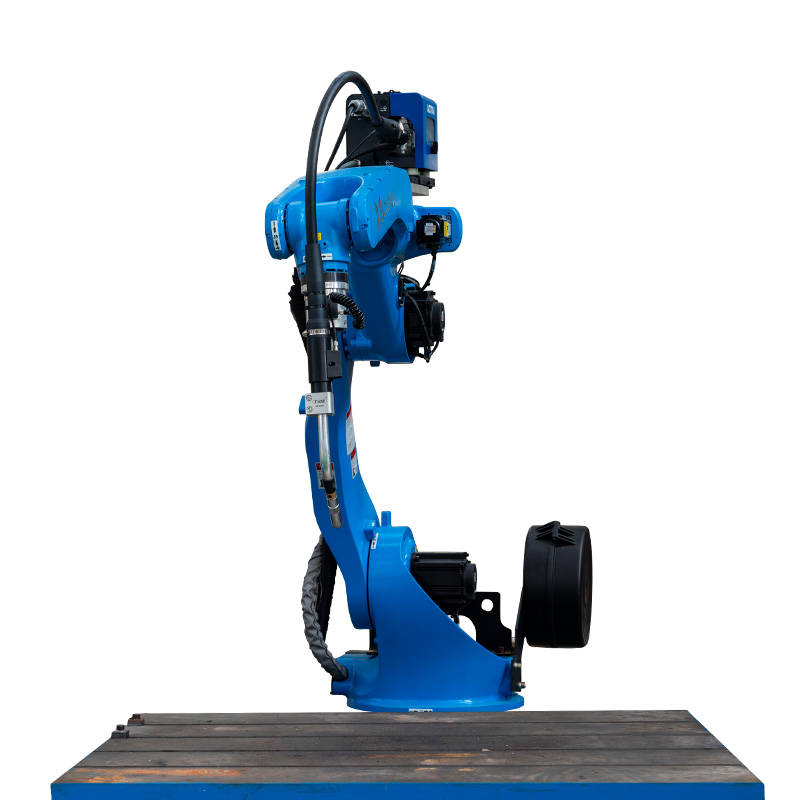

The product cut by a medium-sized machine is a little larger than that of a small machine, but it is the same. The release of the falling body has no effect on the product itself, so we do not have this model. What kind of extra disciplinary action, only the mainframe, we have made an extra disciplinary action, but this disciplinary action should be based on different customer requests, different disciplinary actions, occasionally we will use robotic hands to pick up materials, occasionally we will use conveyor belts When cutting materials, other methods are occasionally used for cutting materials, but the goal is one, so that the blanking assembly of the fiber laser cutting machine can drop the materials more stably.

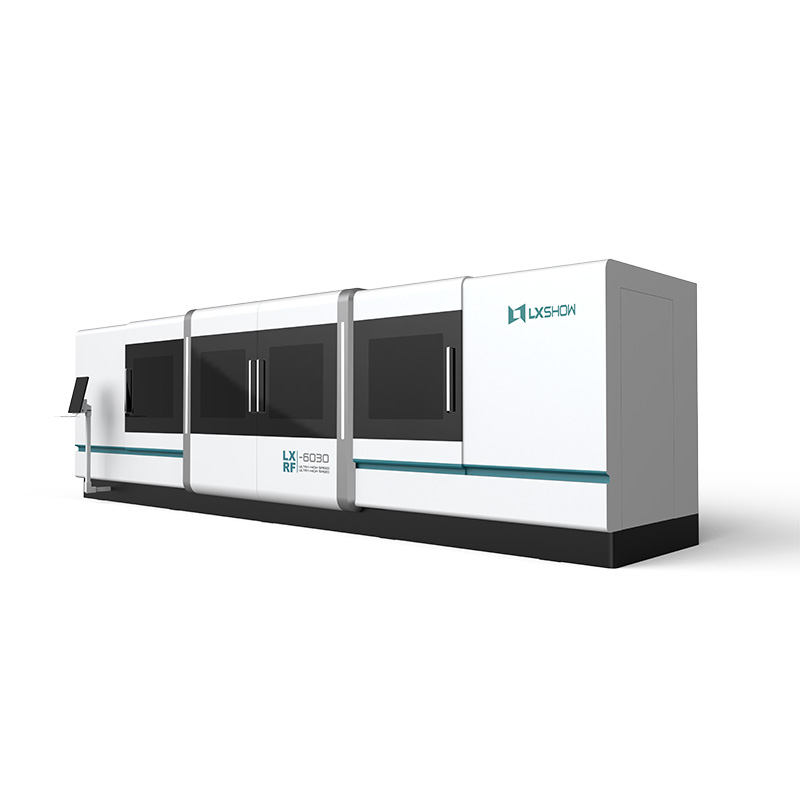

At this time, our factory has also considered for customers. Because the fiber laser cutting machine is different from other equipment, because the material of the tube is relatively soft, if the fiber If the laser cutting machine simply falls off after it is cut, it will damage the product, so defective products will occur. Simply analyze the machine plan and the customer will definitely not take over. Therefore, when our factory planned the all-fiber laser cutting machine, we have dealt with this question as the key point.

Every action of automated equipment is very important. The same is true for fiber laser cutting machines. Customers who live in many places are very considerate of active feeding. The feeding is accurate and strictly prohibited. Can it be delivered? This is a question that customers are often asked. Some very careful customers not only ask about active feeding, they will also ask how your fiber laser cutting machine cuts the material. Is it the liberation of falling body cutting or other careful cutting in the environment of guarded products? Of course, the security products are tense.

Others are better for fiber laser cutting machine models. It’s hard to say. Each model has its own advantages and disadvantages, so choose the right one. The cutting machine for your own workpiece is the better cutting machine.

Stainless steel all-fiber laser cutting machine can actively clamp materials

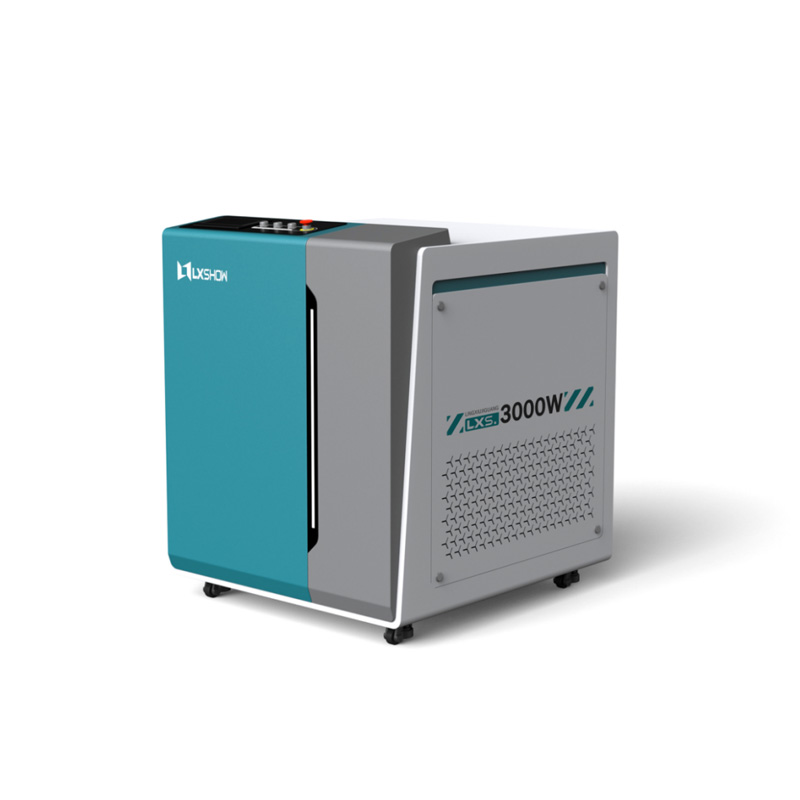

Product morphology: stainless steel all-fiber laser cutting machine 160-31 can actively clamp materials, Feeding, feeding, fixed-size configuration, scheduled shutdown and work measurement functions.

The main circuit of this machine adopts the Japanese Mitsubishi PLC computer controller, which is intensive and portable, vivid and easy to repair. Active feeding, clamping and cutting system ensures accurate and fast feeding. It can cut 4-10 times per minute without damaging the appearance of the workpiece.

The counter can be configured to cut the number of times, and automatically stop after the end of the cutting. The total amount of work that can be counted by the counter is recorded. The total pressure, front, back, and pressure can be adjusted steplessly to ensure that the workpiece is not pinched or deformed. The cutting length is accurate to plus or minus 0.03mm, and there is no burr in the light.

The front clamp, back clamp, knife speed, and feed rate can be adjusted in sections, and the accuracy of the work and the workpiece is under control.

Stainless steel all-fiber laser cutting machine 160-31 type special machine for cutting triangular, hexagonal, round and square stainless steel tubes.

Active working mode: regenerate everything manually, (move right) pull out the subtotal, cut several times and feed several times, then start the motor (motor ON) and press (Starting) The motor won’t start or the saw table can’t work, analyze that the switches are not reset, and can’t take the initiative.

Nine safety points that must be paid attention to when operating the fiber laser cutting machine Incidents

1. The operator must perform the gear shift on the main shaft of the fiber laser cutting machine only after parking the vehicle. In the process of shifting, the gears must be completely meshed. When the fiber laser cutting machine is uncommon, the vehicle must be parked for inspection.

2. Before cutting the pipe, adjust the cutter of the fiber laser cutting machine and clamp the pipe. The length of the clamped pipe shall not be less than 50mm. It is necessary to keep the parking baffle intact, and only after a series of test machines such as responsive clamping, unclamping, forward and backward, can be operated and processed.

3. When the fiber laser cutting machine is rolling, no part of the human body should touch the transmission parts of the machine. In the process of operating the fiber laser cutting machine, the operator must tie up the cuffs of his clothes, and it is strictly forbidden to wear gloves. The human head should deviate from the cutting bias.

4. When exchanging tools, measuring workpieces, clearing pipe heads, or smoothing, all operations must be carried out while parking.

5. When the fiber laser cutting machine cuts the tube head, it is necessary to prevent the cut tube head from flying out and hurting people.

6. When loosening the binding lead wire of the pipe, or putting the long material pipe into the material rack, the response error should be adopted to prevent the pipe from rolling and hitting. It saves the danger to the staff.

7. When using the grinding wheel fiber laser cutting machine, the operator should first check the grinding wheel for defects, cracks or signs of dampness, and check whether the power cord is safe and reliable .

8. It should be ensured that the dust removal assembly of the fiber laser cutting machine is intact before cutting the pipe.

9. The deviation of the receipt and expenditure of the pipe work piece should not stand alone.