Laser radar system of fiber laser cutting machine

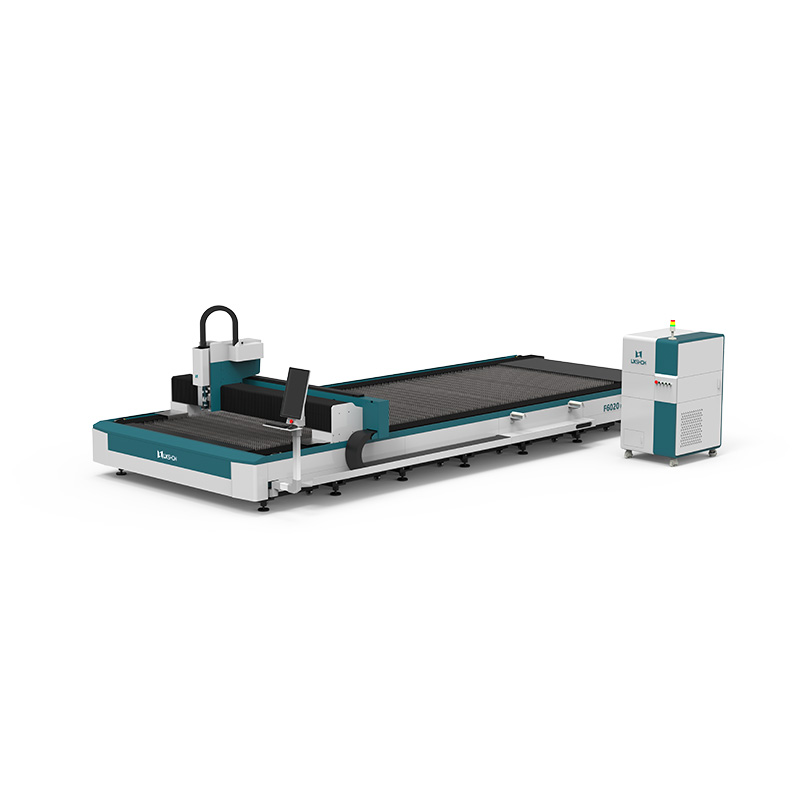

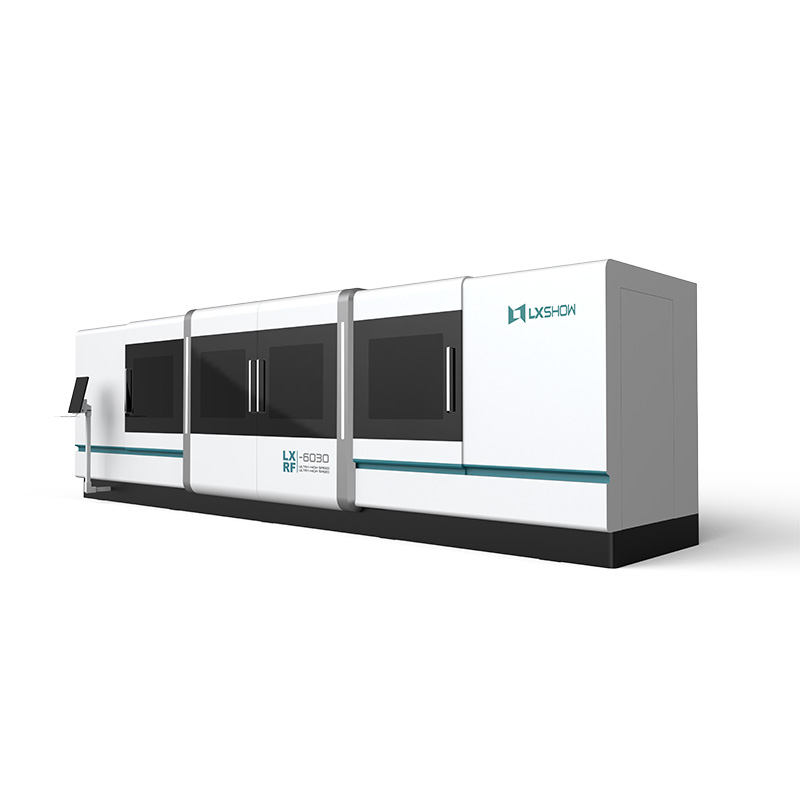

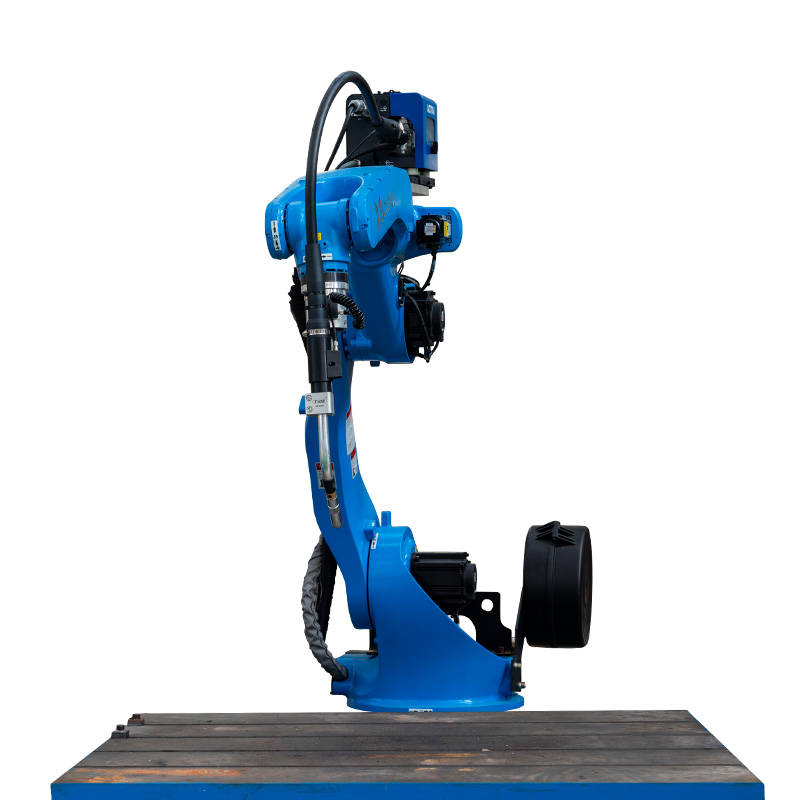

Compared with bulky gas lasers and solid-state lasers, the fiber laser cutting machine has obvious advantages, and has gradually developed into an important candidate in the fields of high-precision laser processing, lidar systems, space technology, and laser medicine. Fiber laser cutting machine can be used for plane cutting or bevel cutting, and the edge screw is neat and smooth. It is suitable for high-precision cutting processing such as metal plates. At the same time, it can be used for three-dimensional cutting with a mechanical arm instead of the original imported one. Five-axis laser. Compared with ordinary carbon dioxide laser cutting machine, it saves air and gas consumption, and has high photoelectric conversion. It is a new energy-saving and environmentally friendly product and one of the world's leading technology products. Fiber laser cutting machine has advantages over CO2 laser cutting machine: 1 ) Excellent beam quality: smaller focused spot, finer cutting lines, higher work efficiency, and better processing quality; 2) Extremely high cutting speed: 2 times that of the same power CO2 laser cutting machine; 3) Extremely high Stability: Using the world's imported fiber lasers, the performance is stable.

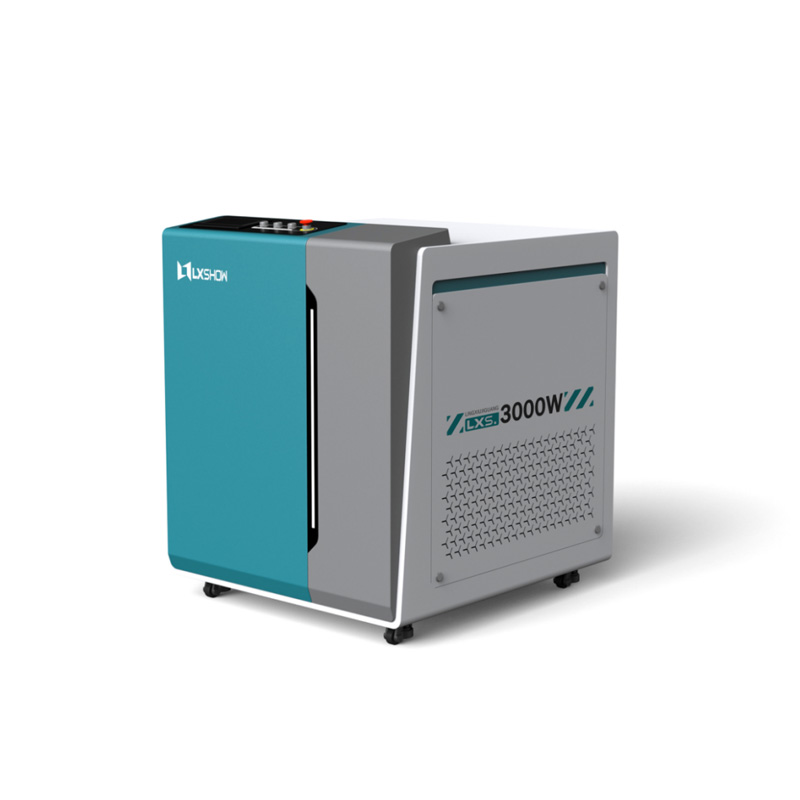

The service life of the key components of the fiber laser cutting machine can reach 100,000 hours; 4) Very high electro-optical conversion efficiency: The optical fiber laser cutting machine has a photoelectric conversion efficiency of about 30%, which is 3 times higher than that of a CO2 laser cutting machine. Times, energy saving and environmental protection 5) Very low cost of use: the power consumption of the whole machine is only 20-30% of the same kind of CO2 laser cutting machine; 6) Very low maintenance cost: no laser working gas: optical fiber transmission, no need for reflective lenses ; Can save a lot of maintenance costs; 7) Convenient product operation and maintenance: optical fiber transmission, no need to adjust the light path; used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, Precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal processing, kitchenware processing and other manufacturing and processing industries. Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum , Aluminum alloy, galvanized sheet, aluminized zinc sheet, pickling board, copper, silver, gold, titanium and other metal plates and pipe cutting. High precision, fast speed, light and narrow cutting, small heat-affected zone, smooth cutting surface without Burr. (2) The laser cutting head will not contact the surface of the material and will not scratch the workpiece. (3) The slit is narrow, the heat-affected zone is small, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.