Fiber Laser Cutting Machine Laser Technology Engineering Center

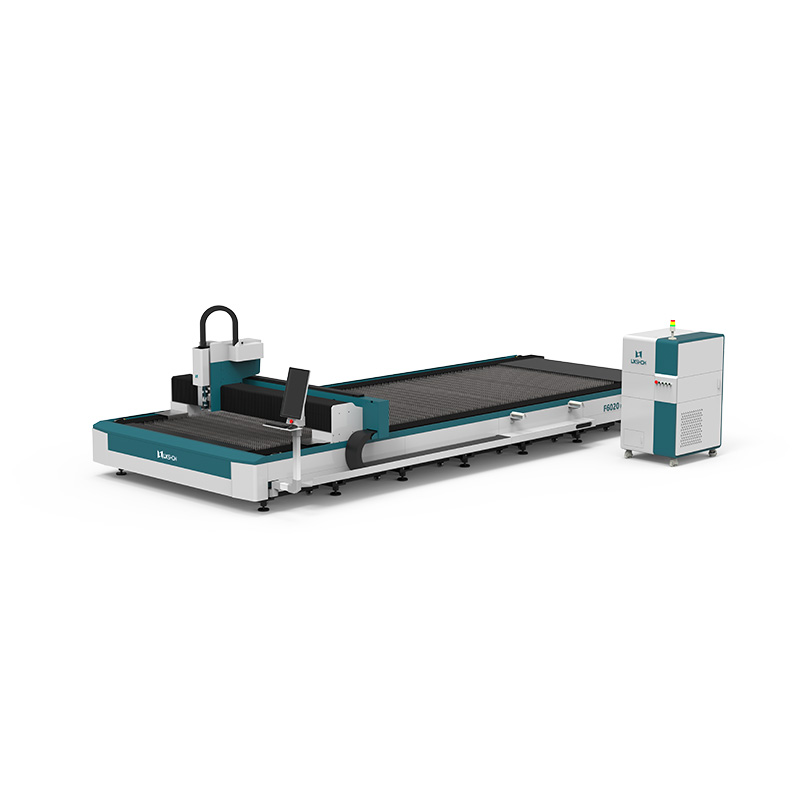

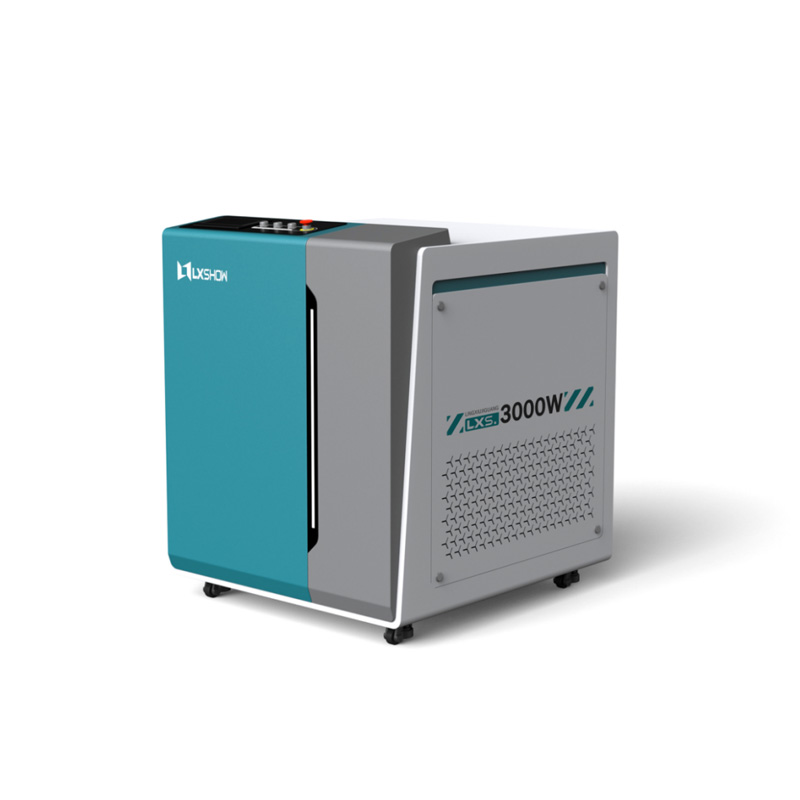

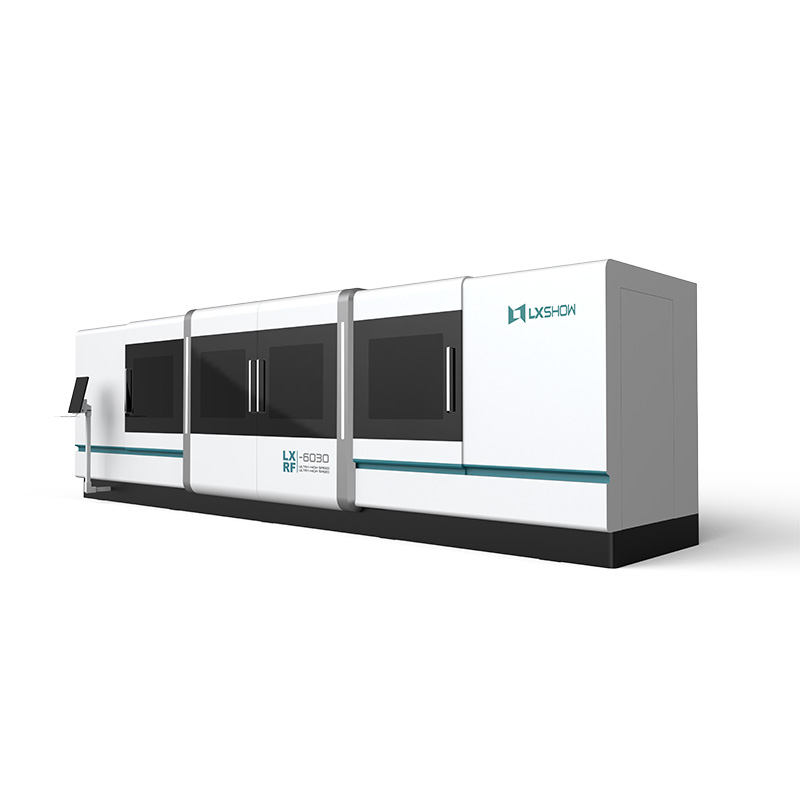

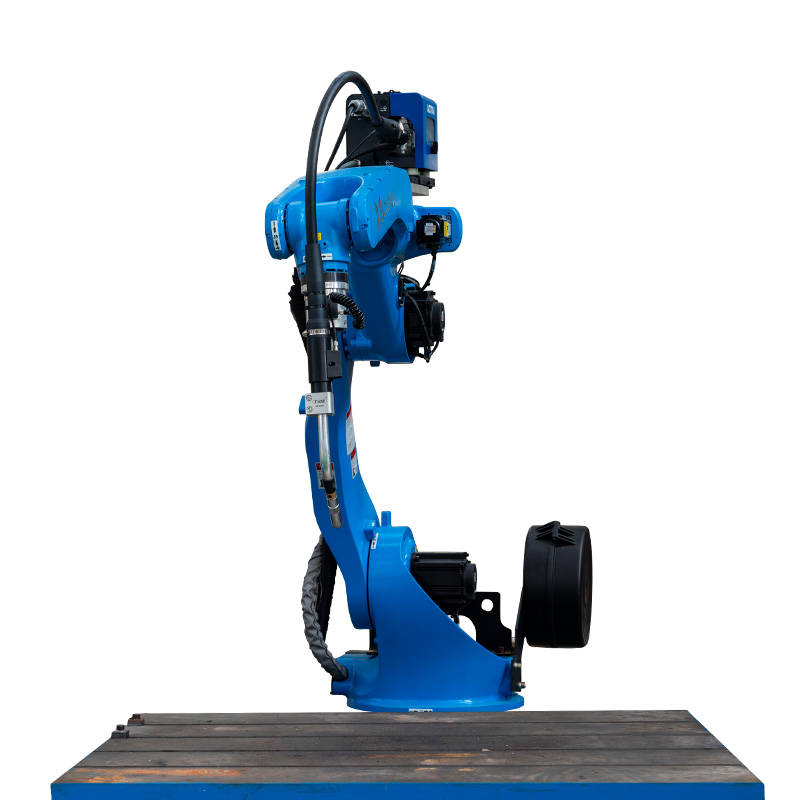

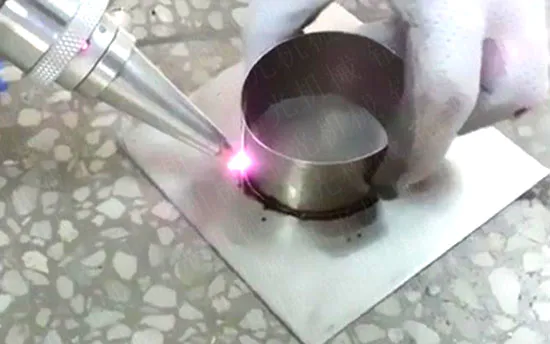

Fiber laser cutting machine was established in Wuhan in 2008. It is a Sino-foreign joint venture engaged in Ru0026D, production and sales; it is also a subsidiary of Zotye Laser Group. The YAG and fiber laser cutting machine series launched by the company help sheet metal processing and other industries and provide industry application solutions for sheet metal processing. The company has a laser technology engineering center, a CNC technology center, a mechanical automation research center, a computer development and application center, and a laser The laser equipment manufacturing industry chain such as the Division, CNC Punch Division, etc. The Ru0026D team is composed of members developed by Jinyun Laser Wuhan. Since its establishment, the metal cutting group has provided small and medium-power metal laser processing solutions. The research and development fields include metal cutting, welding, marking, etc. It is an enterprise integrating Ru0026D, production and sales of complete sets of laser equipment. It was established in 1999 with a registered capital of 10 million yuan. The current products include: medium and high-power laser cutting series, single and double table plane laser cutting series, tube-sheet dual-purpose laser cutting series, three-dimensional tube laser cutting series and more than 100 kinds of products, serving sheet metal processing, environmental protection equipment, Case electric cabinets, agricultural machinery fans, kitchenware and sanitary ware, auto parts, sports equipment, lighting fixtures, metal crafts, household appliances and stoves, communication equipment, food machinery, logistics equipment, advertising, cleaning equipment, doors and windows and other industries. (1) Fiber laser operation Cheng: I am the author of this article. Features and applications of fiber laser cutting machine. Temple point fiber laser has high electrical-to-light conversion efficiency, with a conversion efficiency of more than 30%. It needs to be equipped with a chiller and air-cooled, which can greatly save work time. Higher production efficiency; (2) When the laser is running, only electric energy is needed, and no extra laser generation is required-with lower operation and maintenance costs; the fiber laser adopts semiconductor modular and redundant design, and the output of the fiber laser in the resonator The wavelength is 1.064 microns, does not require start-up time, and has the advantages of adjustment-free, maintenance-free, and high stability.

The maintenance time of the fiber laser cutting machine is unmatched by traditional lasers; the beam quality is good, the power density is high, it is very conducive to the absorption of metal materials, and it has excellent cutting and welding capabilities, thus The processing cost is lower; the characteristics of the fiber laser cutting machine and the application of the machine are optical fiber transmission, no complicated mirrors, etc. The light guide system cutting head contains a protective lens, so that valuable consumables such as focusing mirrors are consumed through the optical fiber Exporting makes the design of the mechanical system very simple. The characteristics and applications of the fiber laser cutting machine can be multiple machines with one device after adding a shutter. Through the fiber splitting, it can be divided into easy-to-expandable functions, convenient and simple to upgrade; fiber laser volume Small, light weight, movable working position, occupying the ground.