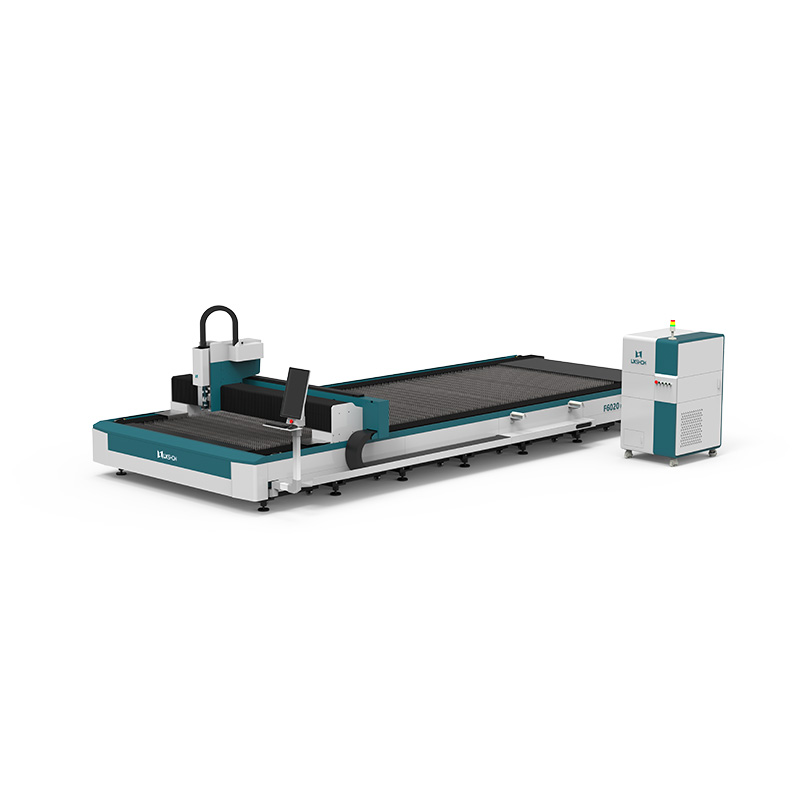

Dust removal device of laser automatic fiber laser cutting machine

Automatic fiber laser cutting machine dust removal assembly, including a part-time table, the bottom side of the part-time table is symmetrical and constant, there are supporting legs, the part-time table is equipped with an automatic fiber laser cutting machine body, and the part-time table is provided with The bottom wall of the cutting groove is provided with a plurality of strip-shaped through holes at equal intervals. The bottom side of the part-time table is fixed with a dust collecting hood, and the bottom side of the dust collecting hood is fixed with an air pump. There is a dust box under the part-time table, the dust box is equipped with a limit assembly, the dust box undergoes limit assembly and continues to have a placement plate, the placement plate is provided with opening teeth, and the opening teeth are unchanged and continuous There is a dust-proof net. This new type of experience servo motor mobilizes the output shaft to roll, so that the cam follows the rolling. The cam squeezes the roller every round, and undergoes the up and down movement of the placement plate. Under inertial use, it will cause the dust on the dust screen. The dust will shake off naturally, and the result will be better.

The automatic fiber laser cutting machine which is convenient for adjustment includes a base, a cavity is arranged in the base, and a rolling adjustment is arranged on the inner wall on the right side of the cavity. The top surface of the chamber is provided with opening teeth, the adjustment member runs through the opening teeth configuration, the upper end of the base does not change continuously with an L-shaped block, and the adjustment member is located outside the chamber and an effective set between the L-shaped block For the clamping part of the unchanging material, the upper end of the base slides continuously and effectively to the cutting mechanism for cutting the material. This book is suitable for the joint application of the new electric slide rail and the second electric slide rail. It is convenient to adjust the position of the laser generator according to actual needs, facilitate the adjustment of the position of laser cutting, and experience the constant change on the second L-shaped block mobilized by the rolling knob. The block is moved around, and the material is clamped unchanged by the spring telescopic rod and bolt, which is convenient for clamping the materials of different sizes.

This article was published by the original